Heat Shrinkable Cable Accessories for Harsh Environments

1. Application of flame-retardant heat-shrinkable cable accessories.

Specific environments such as railways, oceans, government buildings or power plant applications require flame-retardant cables and cable accessories, which needs to meet typical fire safety standards such as IEC-60332 and IEEE-1202. It has become common practice and industry consensus to have cables with accessories conform to these standards to demonstrate their suitability.

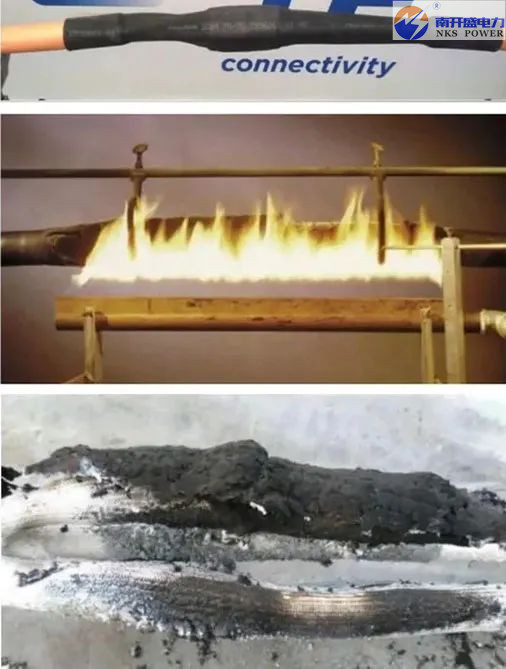

Figure (1): Experiment in which flame-retardant heat-shrinkable termination & joint are arranged in a vertical tray. Image from NKS

2. Fire-proof heat-shrinkable tubes

In addition to flame resistance, specific industry require fire-resistant cables and cable accessories to maintain system integrity for up to 180 minutes. This requirement is much more stringent than flame retardancy and requires a different design approach. Cables, heat shrink termination and heat shrink joints are often covered or combined with Low Smoke Zero Halogen (LSZH) materials to get the benefits they provide. As the name implies, LSZH materials emit low smoke and contain virtually no halogen gases when exposed to fire. However, LSZH by itself will not bring the properties needed for heat shrink cable accessories to ensure the long-term integrity of the system.

Figure (2): Fire-resistant heat-shrinkable joints & terminations before, during and after the fire-resistant test (IEC-60331 standard). Image from NKS

3. Heat Shrink Cable Accessories For Nuclear Reactor Electrical Systems

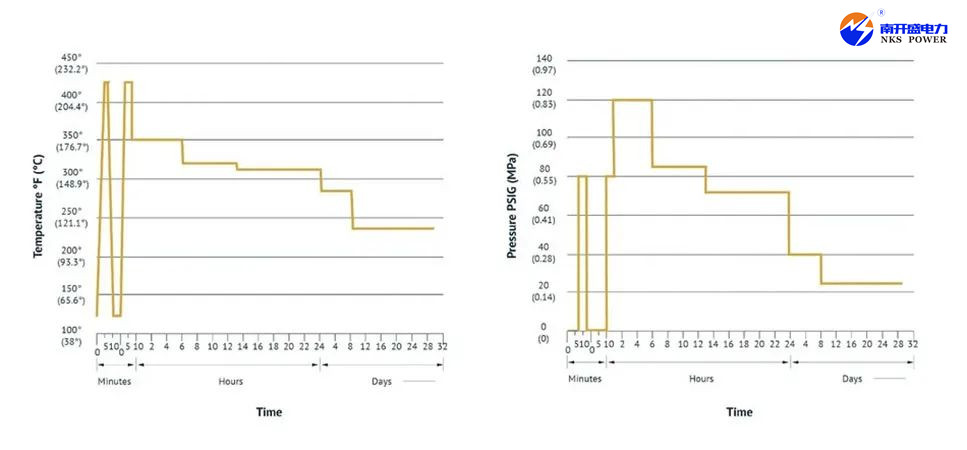

One of the harshest environments for heat shrinkable cable accessories is the containment area of a nuclear power plant, which requires electrical systems to function properly under accident conditions such as a loss of coolant accident (LOCA), one of the worst forms of failure in a nuclear power plant reactor.

In the event of an accident, heat shrink cable accessories should support the operation of emergency functions such as emergency shutdown of the reactor, containment isolation and protection against the release of radioactive material by providing 360° protection of the electrical system.

Figure (3): Experiment: temperature and pressure curves shows performance of heat shrinkable joints and heat shrinkable terminations in a nuclear power plant environment. Image from NKS

4. NKS Power Technology heat-shrinkable cable accessories maintain reliability in the harshest environments.

NKS ‘s heat shrink technology is based on specially formulated thermoplastic polymer materials, optimized for special applications. Heat shrink tubing is known for its high quality, reliability, and ability to withstand weathering processes such as pollution, UV rays, salt spray, and other harsh environments.

Figure (4): Heat shrink tube series. Image from NKS

Sophisticated process controls in the manufacture of NKS’ heat shrink tape, tubing, wraparound sleeves, joints and terminations ensure the product retains its shape memory for decades on the shelf and performs stably in the field after installation 40 years.

Conclusion:

NKS ‘s heat shrinkable cable accessories have been successfully used in LV, MV and HV network. Using them in harsh environments with high UV radiation, heavy pollution, corrosive salt spray and areas where oil resistance, flame resistance or even fire resistance is one of the most challenging areas. The nuclear environment is also one of the most challenging environments today to use heat-shrinkable cable accessories and implement safety-related functions under accident conditions.

LV MV HV Heat & Cold-shrinkable Cable Accessories, Termination & Joint I Separable Connector I Busbar Connector I GIS Termination I Arrester I OEM Manufacturer I NKS

English

English